Würth Elektronik

SAFE AND SIMPLE MARKING OF COPPER FOILS

Würth Elektronik GmbH & Co. KG is a leading manufacturer of PCBs in Europe. Multilayer technology in PCB production, also simply referred to as multilayer, is a technique in order to meet the increasing requirements in electronics. In the multilayer, the inner layer cores with the corresponding prepregs and the outer copper foils are arranged in "multilayer panels". The individual layers are permanently bonded in a press under high pressure and high temperature. A data matrix code (DMC) is automatically applied at the edge of the production panel during production of the inner layer. In the multilayer technique, the inner layers are, however, covered by further copper foils, concealing the ID inside the PCB and rendering it illegible or impossible to assign.

MARKING FOR TRACEABILITY

Machine-readable identification of the respective layers is indispensable when producing multilayers. The relevant recipe data for all produced PCBs can be automatically transferred to the machines or employee at any time in production. All production data collected concerning a product in production may also be collected and evaluated automatically and comprehensively.

ASSIGNABLE AT ANY TIME

Before, the individual layers were marked with the classical manually adjustable stamps and separate ink pads. This production step requires reliable marking that is visible and unique at all times, and that ensures traceability.

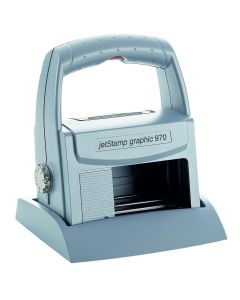

THE JETSTAMP 970 GRAPHIC, ROBUST AND RELIABLE

The marking unit, REINER jetStamp 970 Graphic, is the optimal solution for this demand. The mobile printer prints both consecutive numbers and data matrix codes – mobile, reliable and wirelessly. The data transmission from PC to the mobile marking unit can take place by Windows-based applications, connection to present ERP systems or programming of Excel macros. These may be transmitted by Bluetooth as well as by USB interface, in order to generate the matching print order.

SIMPLE DATA TRANSMISSION BY SCAN AND CLICK

For marking of multilayer PCBs at Würth Elektronik, data transmission takes place through programming of an Excel macro. One-time programming permits simple application for the user. The employee scans the data matrix code of the route card with a scanner connected to the USB interface and transfers it to the mobile marking unit with a click. The imprint, comprising a machine-readable data matrix code and batch ident no. In plain text, can now be positioned precisely. The print order is triggered by clicking the “print button”.

BEST DATA QUALITY IN THE SHORTEST TIME

Precise printing of the information also saves time for the following steps – e.g. because it becomes machine-readable again for the subsequent production steps and permits unique identification and evaluation at a glance.

The benefits at a glance:

- Time saving by optimisation of work steps

- Error avoidance by automated data transmission to the device

- Cost-efficient marking solution by connection to existing software by Excel macro

- Short printing and transfer times

- Marking of dimensional, machine-readable codes and batch ident. no.

- Traceability of the PCBs produced

A CLOSE LOOK AT THE PRODUCT USED

-

REINER P3-MP4 Super Quick Drying Ink Cartridge (glass) - Fits 940 and 970 Graphic

£194.93View DetailsIncl. VAT

£194.93View DetailsIncl. VAT

Despatched in 1-2 working days. -

REINER P3-MP3 Quick Drying Ink Cartridge (metal & plastic) - Fits 940 and 970 Graphic

£153.40View DetailsIncl. VAT

£153.40View DetailsIncl. VAT

Despatched in 1-2 working days.

Need more help?

Our experts are here for you!

Call us on 0121 622 8900 or e-mail us with your requirements and we’ll help you find the right product for the job.

You can also book a demo and see the machines in action.